Transformers

Transformer manufacturers in Navi Mumbai

Transformers are electrical devices used for electrical engineering and power distribution. They play an important role in the transfer of electrical energy in the middle of two or more circuits with the help of electromagnetic induction.

Are you looking for one of the most reliable and trustworthy transformer manufacturers in Navi Mumbai? Yes. We at Marsz Electricals Pvt. Ltd. are here to serve your needs with the best quality of products. The transformers we deal with are made with supreme quality to follow universal standards.

Our interested buyers can easily purchase the products as they are of superb quality, highly efficient, and have a long service life. Additionally, we deliver the products with technical specifications and customise them as per order demand.

Marsz Electricals Pvt. Ltd. is answering the demands of different companies as a service provider of electrical transformers in Navi Mumbai. We are supported by a professional team of qualified and experienced personnel. Our team is ready to support you even after sales. We are happy to shake hands with the clients and internal team, supporting them to get the best results in the market. Contact us now for more information.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Driven Type | Electric |

| Usage | Industrial |

| Color | Blue |

| Surface Finishing | Powder Coated |

| Country of Origin | India |

| Speciality | Robust Construction, High Efficiency |

| Phase | Single Phase/Three Phase |

| AMC Available | Yes |

| Brand Name | Marsz |

Distribution Transformer Trader

A distribution transformer works for the electrical distribution system to cut down the high voltage directly from the transmission system. It is aimed at maintaining the voltage levels and making them suitable for the right distribution to homes, businesses, and sectors. Such products play a significant role in the final stages of the electrical power distribution network.

Do you wish to buy a distribution transformer available at the best quality? Yes. We at Marsz Electricals Pvt. Ltd. are a renowned distribution transformer trader, manufacturer, and supplier based in India, supplying them to renowned countries such as Australia, the U.K., New Zealand, Italy, Germany, East Africa, South Africa, the Middle East, and the Far East.

The distribution transformers we deal with are made with the utmost attention to meet universal standards. Our clients are willing to buy the products because they are of amazing quality, highly efficient, use less power, and have a long service life.

Features of the Distribution Transformer

- Made with robust construction and is highly efficient.

- The surface finishing is powder-coated to give better results.

- Available in two phases: single-phase or three phase

- Made for work in maximum temperature rise at full rated load, 40–50 °C for aluminium wounds and 45–55 °C for copper wound transformation.

At the same time, Marsz Electricals Pvt. Ltd. delivers the products with special technical features. If you wish to make some changes, customised orders are also accepted with us. Our product range is so efficient that it can save power. Our team is focused on satisfying the needs of different firms as a service provider of electrical transformers and maintenance services for transformers.

If you wish to collect more information about the product and delivery, you can contact our team. After-sale help is also available with us.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Color | Blue |

| Condition | New |

| Automatic Grade | Automatic |

| Application | Industrial |

| Phase | Single Phase |

| Country of Origin | India |

| Cooling Type | Oil Cooled |

| Brand Name | Marsz |

MARSZ manufactures Arc, Submerged Arc, Ladle, Induction furnace transformers upto 10 MVA, Upto 33kV, ONAN / OFWF cooling.

A high current furnace transformer is provided by having the low-voltage windings arranged in a closed delta configuration within the transformer enclosure. Bus bar terminals are mounted exterior to the enclosure for providing electrical connection with the low-voltage windings.

MARSZ Furnace transformers are used to step down from voltages between 11 and 33 kV to levels of several hundred volts only. This results in massive secondary currents. As an example a 30 MVA unit at 150 V would result in a secondary current of 115 kilo Ampere. For these high secondary currents special bushings are required to connect to the bus-bars. These bushings are specified with very specific arrangements to suit the bus-bar arrangement and cooling system. Furnace bus-bars are mostly water cooled. Due to the high secondary currents and resistive losses the furnace layout is such as to limit the bus-bar length.

The MARSZ furnace transformers are then located close to the furnace itself and if they are single phase units, arranged in a triangle around the furnace. This means that there is a high risk of fire, a high ambient temperature and this whole set up is located at a level associated with the third story of the building. The location above ground level encourages single phase units due to the structural limitations of the buildings. To reduce the fire risk the transformers are contained in rooms, which adds to the high ambient temperature.

MARSZ Furnace transformers are very much used in a production environment. Loading of these transformers is then very close to rated values and even beyond. This demands very reliable transformers. Shutdowns due to transformer problems are frowned upon. When shutdowns occur, the problem needs to be solved quickly. This in turn calls for good accessibility of the tap changer and other parts of the transformer. Large inspection covers in close proximity to the tap changer are often specified.

Due to the nature of the process MARSZ furnace transformers are specified with large tapping ranges. Thirty tap positions is not uncommon. Adding to the wide tapping range is the utilisation of the tap changer. Some users require up to 800 operations of the tap changer per day. This demands high maintainability and efforts to increase the maintenance intervals. On line tap changer oil filters are thus essential. To reduce downtime further, plug-in type diverters are specified. This allows a quick changeover of the diverter switch and an overhaul in a workshop environment with more time at hand.

Another aspect of the process is the large number of short circuits that these transformers are subjected to every day. Transformers associated with open arc furnaces can be subjected to a number of short circuits per melt as the material being melted collapses across the electrodes. Bus-bar flash overs are also a fact of life on most furnace installations. To add to this peril, MARSZ furnace transformers are required to have a lower than normal impedance. This gives rise to higher over-current factors. Very robust design in terms of the transformers’ ability to withstand the dynamic effects of repeated short circuits is required. Minimum impedance values for furnace transformers of the core type are in the order of 4 – 5 %. To achieve lower values, one would need a shell type transformer. Upper levels for impedance could be any value from 10 to 24 % depending on the configuration and tapping range.

Application in following industries :

Chemical, Pharmaceuticals, Steel, Textile, Engineering, Plastic, Cement, Refineries, Mining, Captive Power Projects, Hydro Power Projects, Wind Mill Farms, Construction Houses, Pharma, Electrical, Electronics, Renewable Energy, Automobile.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Driven Type | Electric |

| Speciality | Robust Construction, High Efficiency |

| Usage | Industrial |

| Country of Origin | India |

| Ranging from | 12V to 660V at 50 Hz / 60 Hz |

| Capacity | 0.5 to 800 KVA |

| Conforms to IS | 2026 / IS : 11171 |

| Brand Name | Marsz |

- Mining Transformer

- Lighting Transformer

- Loading Transformer

- Furnace Transformer

- Auto Transformer

- Rectifier Transformer

No of Phase

- Single Phase

- Three Phase

- Three Phase to single Phase

- Three Phase to Two Phase (Scott)

Type of Transformer

- Double wound Transformer

- Auto wound Transformer

- Type of cooling

- Natural Air cooled

- Natural Oil cooled

Salient Features

- Ranging from 12V to 660V at 50 Hz / 60 Hz

- Capacity:0.5 to 800 KVA

- Taps can be provided with OFF load Tap changer using links or Switch

- Conforms to IS : 2026 / IS : 11171

- Class of insulation class B / F / H

- Efficiency better than 96%

- Regulation better than 5%

Natural Air-cooled transformers are supplied in sheet steel ventilated case, with screwed top cover. Input and output terminals are provided on the top side of the transformer, inside the Terminal Box. Cable entry holes are provided on the bottom side of the Terminal Box. The transformers are suitable for floor mounting and are also supplied with M.S. Rollers for easy portability in case of large size transformers.

Natural oil cooled transformers are supplied in M.S. tanks. In some cases, the tanks are provided with cooling radiators on two or all the four sides. As a standard practice, the tank is provided with oil fitting hole with cap, oil level indicator, drain plug, and earthing terminals. Input and output terminals are brought out generally on two opposite sides, either from the sides of the tanks or from the top of the tank. Plain unidirectional M.S. rollers are fitted on M.S. channels for base mounting.

MARSZ also supplies transformers in open execution, without any enclosure, when they are to be mounted inside a control panel or a cubicle.

The description given below are for single phase, three phase and three phase to single phase double wound transformers. It is valid only for double wound transformers and for phase voltage between 24 volts and 660 volts at a frequency of 50 Hz. For voltages beyond this range and for other frequencies will be made on request.

In case of Auto Wound Transformers though the entire range falls within our regular manufacture, their details depend very much on the transformation ratio, in addition to the capacity. Therefore, special quotations should be obtained in individual cases. These include single phase and three phase Star-connected transformers, auto-boosters and off-load line voltage correcting transformers.

SINGLE PHASE DOUBLE WOUND TRANSFORMERS

As stated before, these are made in natural air-cooled construction or natural oil cooled construction. Extra off-load taps can be provided on request. The capacity of the transformer at the tap will be proportionately low corresponding to the tap voltage. The declared capacity will hold good only for the highest voltage on both input and output, unless the taps are specified as full capacity taps.

THREE PHASE DOUBLE WOUND TRANSFORMERS

These transformers are generally manufactured in Delta/Star or Star/Delta connections. However, transformers can also be supplied suitable for Delta/Delta or Star/Star or Open delta/Open delta connections on request against specific requirements. Enquiries or orders should clearly state the voltage and connection on the primary and secondary and whether the voltage are between phases or between phase and neutral. Extra off-load taps can be provided at extra cost. The capacity of the transformer at the tap will be proportionately reduced corresponding to the tap voltage, The declared capacity will hold good only for the highest voltage on both input and output unless the taps are specified at full capacity taps.

THREE PHASE TO SINGLE PHASE DOUBLE WOUND TRANSFORMERS

These transformers are very widely used where large single phase power is required. These are wound as open delta on the three phase input side and the windings on the secondary are connected in series for single phase output. This type of construction given an unbalance in the supply current. e.g. 10 KVA three phase to single phase transformer will have a current distribution as Phase A : 14.5 Amps, Phase B 29 Amp and Phase C: 14.5 Amp approximately when the supply voltage is 400 volts nominal. However, this unbalance is less severe than when a single phase load is connected between phase and neutral or between phase to phase.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

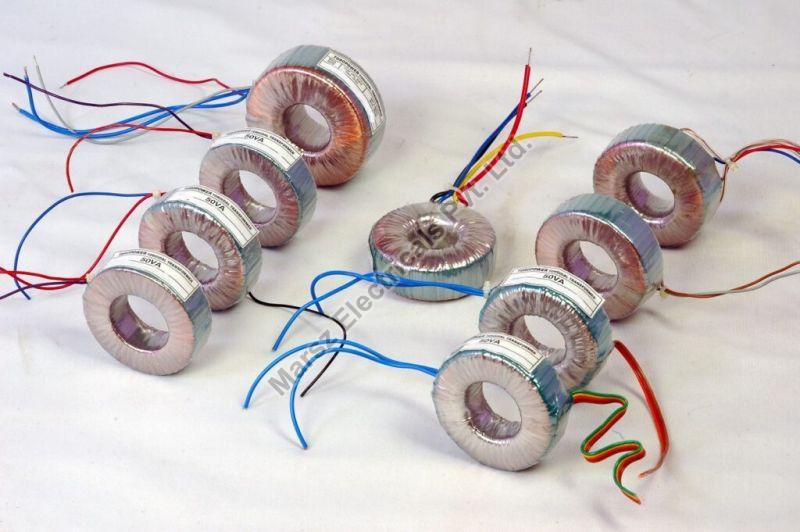

| Driven Type | Electric |

| Condition | New |

| Application | Amplifier, Stabilizer, Voltage Convertor |

| Type | Toroidal Transformers |

| Country of Origin | India |

| Brand Name | Marsz |

A range of high quality toroidal transformers with twin 115VAC. primary windings and a wide choice of secondary voltages.

The primary windings can be connected in series or parallel to cater for 115V or 230V 50/60Hz AC inputs. All leads for both primary and secondary are double-insulated enamelled wire with stripped wire ends thereby reducing assembly time.

There are no air gaps in the core & no vibrating laminations. The reluctance is low, resulting in very low magnetizing currents with savings in power consumption. A further benefit of this gapless core is the reduced level of radiated electrical noise (hum field).

The simple construction of the toroid and the resultant saving in weight as compared to the conventional laminated transformers makes this range particularly attractive for compact power supplies and slim line equipment. Weight of conventional laminated transformer of 1 KVA is approx.12 kg. whereas weight of TOROPOWER toroidal transformer is approx.7 kg.

Features

- Dual standard primary windings 115/230V AC

- Small size and low weight as compared to traditional stacked lamination type transformers.

- Supplied with mounting kit having a single hole mounting arrangement.

- 100% electrical and flash tested.

- High quality manufacturing and testing.

- Extremely low level of radiated magnetic field.

- Very low induced noise (hum)

- Very low iron loss & magnetizing current & good regulation

- Double insulated leads

Note

Twin 115V AC. 50/60Hz primary windings may be connected in series for 230V or in parallel for 115V operation. Twin secondary windings may be connected in series or parallel or can be used independently. Each transformer is supplied with a dished washer, protection pads and nut, bolt and washer for single hole fixing. The pads are to be fitted above and below the transformer winding and the dished washer on top of the upper pad. Under no circumstances should both ends of the fixing bolt contact a metal chassis or frame as this would create ‘a shorted turn’ causing irreparable damage..

Auto Wound Transformers

A range of high quality toroidal transformers with one 230V AC. winding and tapping’s provided as per requirement. All leads for both input and output are double-insulated, enameled wire, with stripped & tinned wire ends thereby reducing assembly time.

There are no air gaps in the core & no vibrating laminations. The simple construction of the toroid results in saving of weight as compared to the conventional laminated type transformers.

High conductivity copper winding on insulated toroidal core, made of high grade cold rolled grain oriented silicon steel ensures very low magnetizing currents & results in saving of power consumption, making this range particularly attractive for compact power source and slim line equipment. A further benefit of this gapless core is the reduced level of radiated electrical noise (hum field).

TOROPOWER range of toroidal transformers are available

- With Voltages as per customer’s specifications up to 600 volts max.

- Also in sheet steel Enclosed or Resin cast models.

- With shield Between Primary and Secondary windings if required.

Features

- 230 V A.C. Input & 115 A.C. Output 50/60 Hz.

- Popular voltage tapping’s 220-240 V A.C. also feasible.

- Negligible wave form & power factor distortion.

- Excellent short time overload capacity.

- Small size and low weight as compared to traditional stacked lamination type transformers.

- Extremely low level of radiated magnetic field.

- Very low induced noise (hum)

- Very low iron loss & magnetizing current & good regulation

- Double insulated leads

- Supplied with mounting kit having a single hole mounting arrangement.

- 100% electrical and flash tested.

- High quality manufacturing and testing.

Note

Each transformer is supplied with a dished washer, protection pads and nut, bolt and washer for single hole fixing. The pads are to be fitted above and below the transformer winding and the dished washer on top of the upper pad. Under no circumstances should both ends of the fixing bolt contact a metal chassis or frame as this would create ‘a shorted turn’ causing irreparable damage.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Ratio | 415 V / 415 V 3ph or 240 /240V 1ph. Nominal |

| Acceptable Input Range | ±10% |

| Mode of Operation | 1:1 |

| Isolation Transformer Frequency | 47 to 63 Hz. |

| Common Mode Noise Rejection | Over 100 dB |

| Coupling Capacitances | 0.012 PF |

| Dc Galvanic Isolation | Over 500 Megohms Between Any Winding or Windings to Ground |

| Breakdown Strength | 2500 VAC for 2 minutes |

| Load Regulation | Within 3 to 5 % |

| Termination | On Terminal Plate |

| Brand Name | Marsz |

Sailent Features:

Isolation Transformer:

Any Double Wound Transformer is internally an isolation transformer as the primary and secondary are isolated from one another through insulation. However, modern machines and systems need a truly isolated, clean and stable power requirement. This is ensured by an Ultra Isolation Transformer (UIT), it provides for total electrical and electrostatic isolation with most effective screening of spikes, surges and transients, further it gives a true isolated local neutral and dedicated earth which is very essential for modern machines. Ultra isolation Transformer attenuates common mode noise and transverse mode noise and provides for noise or interference free power. In principle, UIT only transfers 50 Hz. Power by transformers action through mutual inductance. It prevents transfer of RF and HF disturbances with extensive insulation between primary and secondary. The insulation levels withstands HV breakdown strength of 2.5 KV and gives a DC Galvanic isolation of above 1000 MΩ.

Ingress Protection for enclosure for isolation Transformer:

MARSZ Isolation Transformer conform to IP-20 protection as per IS / IEC : 60529 : 2001 Requirements for other degree of protection can be offered on request.

Details of Earthing for Isolation Transformers:

It is recommended that every isolation Transformer should have its own grounded earth, complete in itself.

Constructional Features of Isolation Transformers:

Isolation Transformer shall invariably be in one air cooled section. The enclosures are constructed from M.S. angles and CRCA M.S. sheets of best quality. The professional painting process comprises of (i) 7-tank pre-treatment (ii) Primer Coating and (iii)Two coats of final finish paint or powder coating of specified shade.

Ordering Information

- Input voltage

- Output voltage.

- Capacity

- Number of phases

- CMNR value

- Coupling capacitances value.

| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Finishing | Powder Coated |

| Driven Type | Electric |

| Color | Grey |

| Operating Type | Automatic |

| Speciality | Robust Construction, High Efficiency |

| Usage | Industrial |

| Phase | Single Phase, Double Phase, Three Phase |

| Country of Origin | India |

| Brand Name | Marsz |

“VARIVOLT“ is the most effective device meant for operation from a nominal input voltage of 240V 1Ph & can give output voltage anywhere between 0 to 240V or 0 to 270V 1Ph by simple transformer action. Three such “VARIVOLT“ connected electrically in star and mechanically in tandem, become suitable for operation from a nominal input voltage of 415V 3Ph and can give output anywhere between 0 to 415V or 0 to 470V 3Ph.

“VARIVOLT” AUTO TRANSFORMER is a continuously variable voltage auto transformer, having a movable carbon tip, fixed to brush arm sliding on a silver plated commutator. Rotation of the brush arm by either manual or motor drive, delivers an output voltage from zero to or above line voltage. “VARIVOLT” conforms to I.S. 5142.

Salient Features:

- Rugged Construction : “VARIVOLT” Auto transformers are designed for heavy duty trouble free operation. All components are designed to give maximum life to the unit under extreme operating conditions. Except for carbon tips, no other part needs any specific maintenance . Even carbon tips do not require to be changed frequently. This practically makes the “VARIVOLT” a maintenance free electrical equipment.

- Excellent Regulation : The drop in voltage from “no load to full load” is minimal in “VARIVOLT” Auto-transformers. (See fig…II for regulation characteristics)

- High Efficiency : Careful copper, core selection and design assures the user of low watt loss, as compared to other controllers.

- No Wave form Distortion : “VARIVOLT” provides an output voltage wave-form, which is a distortionless replica of the input voltage wave-form.

- Silver Plated Commutator : A special silver plating technique is used on the commutator, enabling it to withstand high overloads and maintain constant contact drop. It also ensures smooth operation, long life and increased resistance to corrosion.

- Over-load Capacity : Because of its careful designing, “VARIVOLT” can withstand many over-loads, Fig…I gives an idea of the maximum overloading allowed with its relevant time limits. When repeated overloading takes place, care has to be exercised to provide sufficient off time to reduce the temperature build up.

- Low Operating Torque : A glass smooth commutator, special sintered bushings for the shaft and perfect assembling of coils results in low operating torque for all “VARIVOLT” Auto-transformers.

- Smooth and Linear Output : As voltage between turns is small and as the brush arm is in constant contact with more than one turn, harmful sparking is avoided and output voltage can be set to a fraction of a volt from zero onwards.

- Low Magnetizing Current : By using an adequate section of high quality grain oriented silicon steel, the iron losses in “VARIVOLT”, are controlled to the minimum. The no load current in all “VARIVOLT” transformers, is invariably less than 3% of the rated current.

- Negligible Maintenance and Trouble Free Long Life : “VARIVOLT” has been carefully designed. No special care has to be taken to maintain “VARIVOLT” auto transformers in normal working environments. The only components needing inspection and maintenance are the carbon tips and the commutator. Timely replacement of carbon tips and cleaning off foreign particles and accumulated dust, from the commutators surface, will ensure a considerably long, maintenance free, and uninterrupted life to the unit. Normally “VARIVOLT” auto transformers up to 28 Amps. are offered in air cooled or oil cooled construction. Models of 40 Amps. & above are offered in oil cooled construction. In very special cases “VARIVOLT”, above 40 Amps, can be offered in air cooled construction. This is possible due to the special paralleling techniques adopted by us.

Auto Transformers – Our Speciality :

“VARIVOLT” is now available in high current ranges from 225 Amps. up to 2000 Amps. in single, two and three phase models. Special paralleling techniques designed by us, have made it possible to surpass the previous current limit of 200 Amps. for toroidal Auto Transformers.

The following are the salient features of High Current “VARIVOLT” Auto Transformers :-

- Special forced current paralleling techniques, result in current sharing of each coil ±2%.

- Flanged type pressed steel radiators, are supplied separately packed, making the units easy for transportation.

- Gear Driven High Torque A.C. Synchronous Motor drive.

- Terminals in the form of bus-bars.

- All other features of oil cooled auto transformers.